CNC lathes are marvels of recent engineering, built to conduct precision machining with amazing accuracy. Listed here’s a breakdown of how they work:

“Growing abilities is always a difficulty listed here at KutRite. It’s all about worth. We ended up outsourcing intensely – 30 percent – at high Price; but at the time we started obtaining our very own Haas machines, we have been capable of deliver that work back again into our facility.”

No matter if it’s for aerospace elements that demand micron-degree precision or automotive parts demanding sturdy repeatability, these machines stand within the forefront.

Our toolroom lathes and hardinge super-precision machines are only a few examples of how we equip our clients with the tools needed for precision work that stands out within the business.

Turret headstocks feature a rotating turret that retains several tools, making it possible for for swift tool adjustments during machining.

When you have any questions about our machines, or curiosity in starting a brand new machining process. Our qualified crew are in excess of satisfied to aid.

Multiple functions – Sliding headstock automatic lathes can engage the material with various tools simultaneously enabling for complex operations.

Short set-up situations, highly dynamic drives and trusted operational safety assurance the proverbial efficiency that characterises our CNC lathes.

The spindles of the high precision lathe are oil cooled. They are also integrated, meaning they don't have belts or pulleys, leading to a lot less sounds and a much better area end. All this raises accuracy and decreases machining time.

It is usually feasible to setup powered tools that may also conduct milling operations around the workpiece. Off-center milling functions for complex workpieces will also be carried out using a Y-axis.

Dependant upon the machine design, a disk magazine or chain journal automatically supplies the spindle with tools.

This innovation will be the primary reason why swiss lathes are so precise. The workpiece moves out to fulfill the tool, which suggests which the lateral drive experienced through the aspect is significantly smaller a result of the minimized instant arm. This, in turn, allows for highly precise machining.

In relation to CNC get more info lathes, choosing a respected model will make a big distinction in the machining operations. Here are several of the highest models you'll want to think about:

These lathes are great for earning spherical parts. The bar stock is fed in the collet along the Z-axis, plus a stationary tool cuts the rotating bar stock. This setup is ideal for simple, symmetrical parts like rods and shafts.

Taran Noah Smith Then & Now!

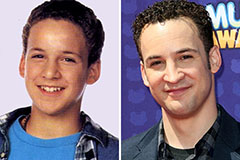

Taran Noah Smith Then & Now! Ben Savage Then & Now!

Ben Savage Then & Now! Kelly Le Brock Then & Now!

Kelly Le Brock Then & Now! Lisa Whelchel Then & Now!

Lisa Whelchel Then & Now! Sarah Michelle Gellar Then & Now!

Sarah Michelle Gellar Then & Now!